FITTINGS WELDED FROM STAINLESS STEEL IN VORONEZH

Cooked fittings are used to create non-detachable seed points. They are installed:

- in sections of the pipeline with high pressure and temperature, under the inflation of mechanical loads (blows, vibrations, etc.), working in aggressive environments where leave is acceptable;

- in areas that do not require constant maintenance.

WELDED FITTINGS FROM ALFA STAR COMPANY

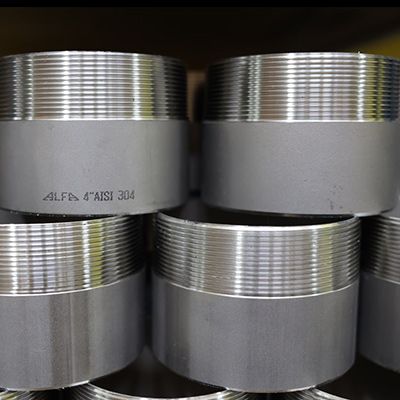

We production and supported fittings according to DIN and GOST standards of high quality at affordable prices. Material of manufacturing - steel AISI 304, AISI 316, AISI 321,12(08)H18N10T, 03H17N14M2T. In the range of the company:

- the collars are stainless, serving to create a connection with free flags. A pair of collars is welded by ends to ends of pipes with free flags put on them, then flags are silent with fasteners. Since there is no contact of free flags with the working medium, flanges of cheaper silumin can be used on non-stressed sections of the pipeline;

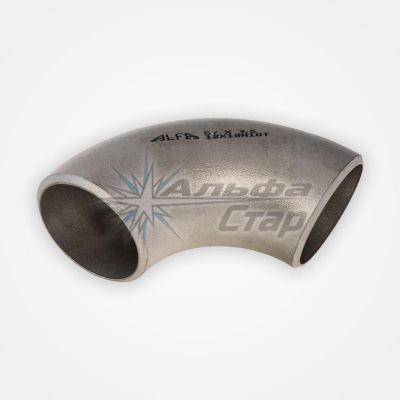

- taps, creating turn's in the pipeline at a Given angle. We offer 90o taps, the most common used, of two types - electric welded recording to DIN standard and seamless GOST. Electric welded taps as less durable due to the presence of a season are used on non-stressed sections of the pipeline;

- transitions steel stainless. Create a smooth and safe transition from one pipe diameter to another. Concentric transfers DIN and GOST are used to connect pipes with coinciding axes, eccentric - for displaced area;

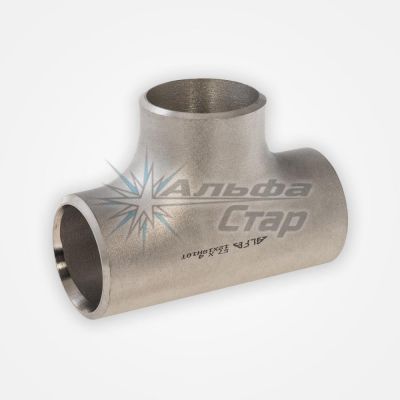

- tees welded for distribution of working flow. In our catalog are tees electric welded DIN and seamless GOST;

- plug's made of steel elliptical DIN and GOST. Create dead-end sections in the pipeline. The elliptical shape allows you to evenly distribution the pressure: the plugs withstand a hydraulic shock of up to 16 MPa.